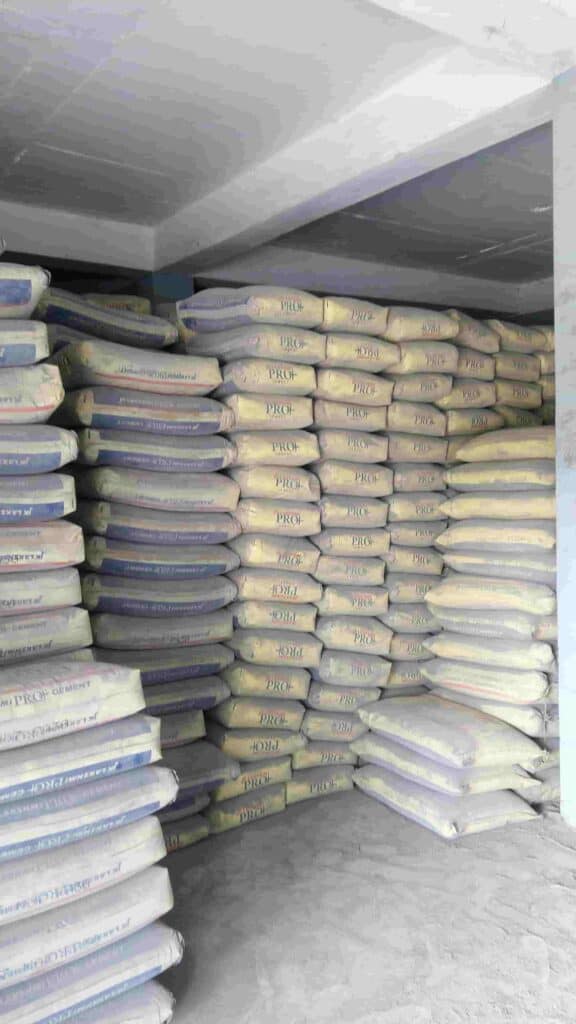

cement ware house

Storage of cement bag

Storage of cement bag as per IS code that height of stack shall not be more than 10 cement bags to prevent lumps due to under pressure. But practically some store supervisor allow the height of stack more than 15 cement bags due to shortage of space. This excess height of stacking not affect the properties of cement(due to pressure) in case of regular removal of cement bags according to FIFO system.

Basic rule of storage of cement in warehouse that cement bags should not touch the roof and don’t place cement bags directly on concrete or wooden floors. Stack of cement bags should be of such height which can easily handled. To guard the cement bags from floor against dampness ,plank or iron sheet should be provided.

Minimum space should be made available in between every group of stacked cement bags in a manner which permit easy access to store staffs or labour for proper inspection, stacking, removing, handling and loading.

Avoid contact between cement bags and side wall of cement warehouse during storage of cement bags and the distance between stack and adjacent side wall not less than 300mm. If cement bags come in contact with moisture present in wall of cement warehouse then lumps should be developed.

Door and windows should be air tight. Avoid storage of cement bag near door area, its causes lumps in cement due to regular contact with atmosphere. Store different types of cement and different brands of cement separately. The cement should not be stored for more than 3 months.

Once the cement bags stored in warehouse it should not be disturbed until delivery. Owing to pressure on the bottom layer of bags sometimes ‘warehouse pack’ is developed in these bags. This can be removed easily by falling the cement bag from a small height and rolling the bags before the cement is taken out for delivery.

Cement bags should be stacked in Header and Stretcher position to avoid free circulation of air. Cement industry provide extra money(storing charges) to labours for stacking cement bags in alternative way like stretcher and header position.

Its provision not to store cement bags not more than three months but practically sometimes its necessary to store cements bags in warehouse for a long period due to irregular deliveries of cement. Some bags damaged due to excess lumps for long period storage of cement, some bags weight less than its standard weight and cut in bag due to defective manufacturing process. So that cut/Damaged cement bags should be kept separately for laboratory testing and bulk billing.

Its seen that most of storing of cement bag in warehouse not as per SOP which pre defined by Engineer or Technical officer. After delivery of cement bags ,the buyer dissatisfied with the cements due to poor management in storage of cement. Due to some improper procedure of storage of cement, many cement brands are suffering defamation.