Ordinary Portland Cement was the most used cement as 33 grade,43 grade and 53 grade in the construction world as a basic ingredient of mortar, concrete and RCC etc. It is a fine chemical powder, produced by heating limestone and clay minerals.

Ordinary Portland Cement(OPC) contain lime as clinker(95%) and gypsum (5%).Difference between Ordinary Portland Cement and other cement is its contain maximum percentage of lime stone(Clinker) and provide more initial setting strength compare to Portland Pozzolana Cement, Portland Slag Cement and Composite cement.

In case of Ordinary Portland Cement heat of hydration is more faster than others and it gains 95% early strength at 7 days of curing. Ordinary Portland Cement mainly consists of lime ,silica, alumina and iron oxide as raw material.

Portland Pozzolana Cement(PPC) is a variation of Ordinary Portland Cement .Generally fly ash added to OPC as pozzolana material to produce Portland Pozzolana Cement. Portland Pozzolana Cement contain fly ash not less than 15% and not more than 35% by weight of cement ,5%of gypsum and rest amount of Portland cement clinker.

PPC has low initial setting strength compared to OPC but it gain more than standard strength at 28 days. As compare to OPC , heat of hydration of PPC is less faster. PPC provide more strength than OPC in a long time duration. PPC has higher concrete density compare to OPC so that PPC is suitable for coastal area construction with aggressive weather conditions.

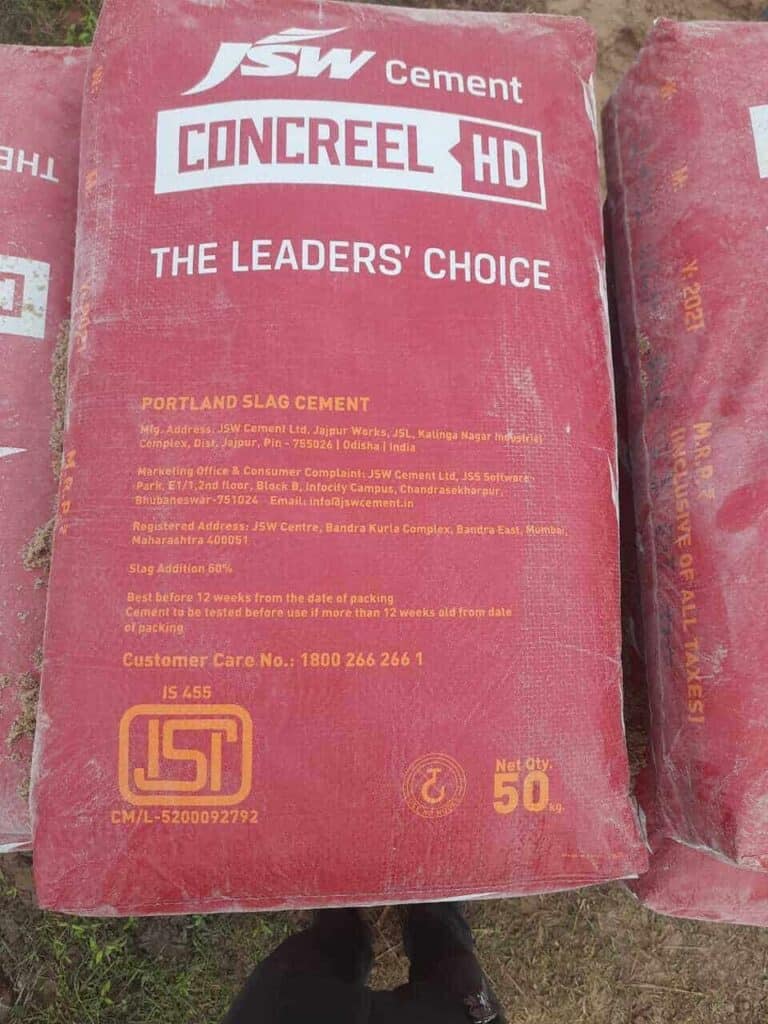

Portland Slag Cement(PSC) is manufactured by blending a mixture of Ordinary Portland Cement and slag instead of fly ash, in proportion not less than 25% and not more than 65% by weight of cement,5% of gypsum and rest amount of Portland cement clinker.

Portland Slag Cement(PSC) consumes 30% less electrical energy during production. Another major difference between Ordinary Portland Cement and Portland Slag Cement is that Portland Slag Cement provide greater compressive and flexural strength at later age (after 7 days) where OPC deals with quick strength. PSC has lower heat of hydration.

Composite Cement has no similar chemistry to OPC but its combination of Portland Pozzolana Cement and Portland Slag Cement. Composite cement contain declared percentage of fly ash and slag.

In Composite Cement the content of fly ash not less than 15% and not more than 35%,content of slag not less than 20% and not more than 50%,5% of gypsum and rest OPC clinker.

This composite Cement gain more than standard compresive strength (33Mpa,min) in 28days of casting. Now a days most of cement company produce composite cement as their premier brand as example Platinum Supremo Cement, Dalmia Composite Cement, COMP CEM, Maha Solid Cement, ROOFON Cement etc.