Composite cement is combination of Portland Pozzolana Cement and Portland Slag Cement. Both slag and fly ash used in composite cement provide an extra advantage in strength development and increase concrete performance. Composite cements provide a compressive strength of more than 33 MPa at 28 days of casting.

Composite cements are cements in which a proportion of the Portland cement clinker is replaced by fly ash (also known as pulverized-fuel ash or pfa),slag(granulated blast furnace slag).Under IS: 16415-2015, Composite Cement is covered and offers a fantastic opportunity to create highly durable, high-strength concrete.

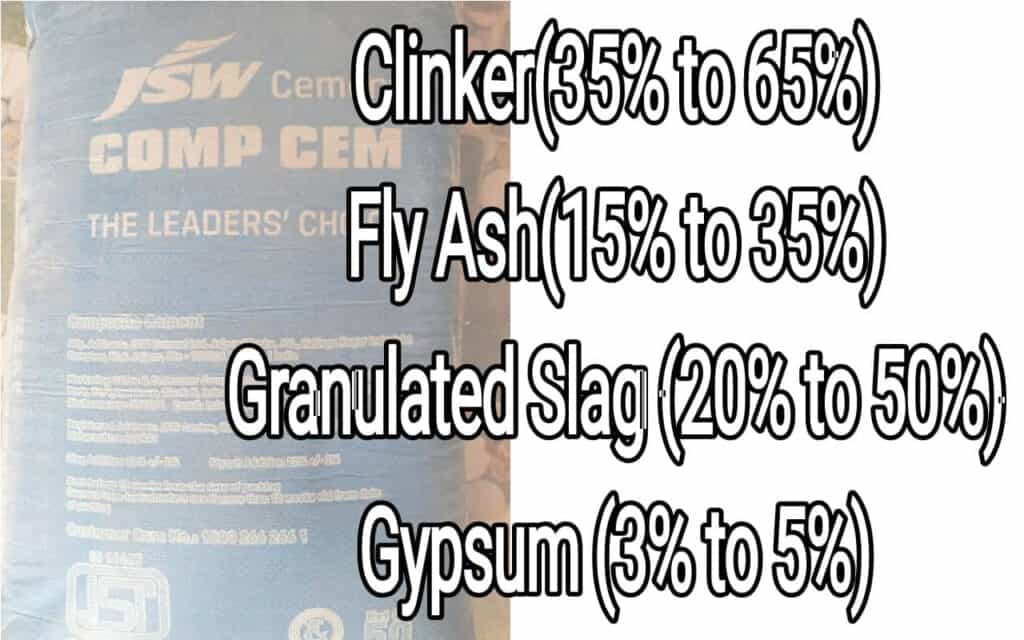

High grade clinker (IS:16353-2015), fly ash (IS:3812 (Part 1) – 2013), granulated slag (IS:12089-1987), and gypsum are combined to produce composite cement. Clinker (35% to 65%), fly ash (15% to 35%), granulated slag (20% to 50%), and gypsum (3% to 5%) make up the typical range of these components.

This contemporary product is the result of the homogeneous blending of highly reactive fly ash, slag with a high glass content, and high-quality clinker, and it offers both consumers and society as a whole a number of advantages. The cement company’s Composite Cement is perfect for coastal areas since it has alkaline and sulphate resistance qualities. This cement is extremely advanced, providing ordinary Portland Cement with better cohesiveness, superior workability, and a lower water requirement.

By replacing a higher percentage of clinker and having a lower carbon footprint than general used cement, composite cement offers a better possibility to save natural resources and mines, namely limestone, without losing the properties and characteristics of concrete . Many cement companies are approving and producing composite cement for various concrete applications in the construction industry.